3 min read

How To Calibrate A Universal Testing Machine With Minimal Downtime

oleh : Jul 1, 2019 12:00:00 AM

There are many technical factors to be considered when you need to have your Universal Testing Machine calibrated. What size load cell(s) does your machine have? Do you need calibration performed in tension, compression or both? Is there an associated extensometer calibration required?

Finally, after all the technical questions have been answered, it’s time to reach out to a vendor and schedule the onsite visit. This is when you quickly realize that one of the roadblocks many fail to consider is how long it takes to schedule a vendor to come onsite to perform the calibration.

There aren’t a lot of options when your chosen calibration partner confirms they can calibrate a Universal Test Machine, but it will take two months to get it done. This may be acceptable if it’s a scheduled calibration event. However, if a machine goes down and needs to be recalibrated, it can be a nightmare for a production team. Finding a calibration partner who is responsive, knowledgeable and cost effective can be one of the biggest challenges you face when it’s time to calibrate your Universal Testing Machine. The good news is your search is over.

Calibration Services On Your Schedule

Welcome to the first of a new series of blogs and articles on calibrating some of the most common measurement instruments and machines in the workplace today. We’re going to talk about the key issues in the calibration process. At our core, PCS values customer responsiveness and helping our customers minimize downtime attributed to calibration. We are here to help ensure your Universal Testing Machine calibration is completed on your schedule by knowledgeable technicians.

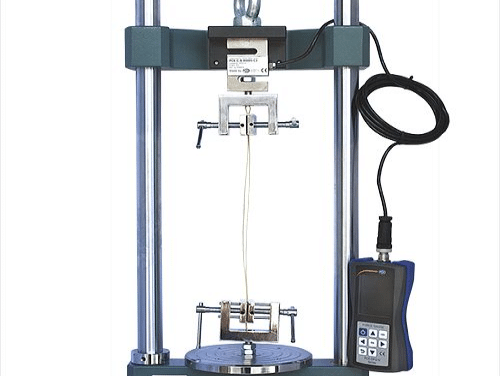

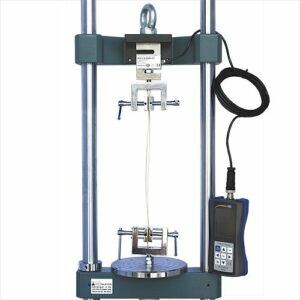

Introduction to the Universal Testing Machine

Universal Testing Machines (UTMs) are the subject of this post. Tensile testers, compression machines, and the like are in great demand because their functions are instrumental in so many industries. Most of us know them in their traditional role of verifying strain specifications such as bend, extension or compression of materials. These versatile machines are also used to check tape adhesion in packaging designs, delamination force of bonded layers of materials in semiconductor processes and many more applications.

Why Calibrate a Universal Testing Machine?

Most quality control systems require periodic calibration of instruments, testers or machines that provide measurements of product parametrics. This practice makes sure the manufacturer’s published specifications are always met. In addition, the calibration process makes these measurements traceable to a known standard, such as the National Institute of Standards and Technology (NIST). Material properties are typically verified and validated at the design stage but can change as processes are revised and developed. A calibrated Universal Testing Machine ensures a product’s material properties in the production phase are always within the tolerance window established in the design phase and are referenced back to a NIST standard.

How is a Universal Machine Calibrated?

In order to ensure the calibration process for machines and instruments is identical, regardless of who performs the procedure, detailed standards have been developed over many years. ASTM International, formerly known as the American Society for Testing and Materials is one of the largest developers of voluntary standards in the world. They produce the de facto standard set for most organizations who require equipment and instrument calibration. PCS follows ASTM standards when developing all of our calibration procedures.

ASTM E4 for example, specifies the procedure for calibrating tension and compression force generation in a Universal Testing Machine. Since force is a vector, ASTM E4 includes details like the correct location of connection points to the load and the resultant magnitude and direction of the forces to be applied. ASTM E4 requires two runs of machine readings as compared to a known standard to verify each calibration instance is within an acceptable tolerance. Common standards for the UTM include ASTM E2658 and E2309 which handle UTM crosshead velocity (speed and displacement). ASTM E2624 deals with torque, while E467 addresses dynamic force, sometimes known as impulse testing.

Extensometers and Universal Testing Machines

One of the more difficult measurements manufacturers have to make is the minute effects of tensile and compressive forces on the length or width of load bearing materials. Statistical extension and contraction norms must be found that encompass the variation in both materials and the manufacturing process before commercial specifications of such can be published in a manufacturer’s data sheet.

Extensometers are highly accurate machines used to measure the very small physical response to forces applied by the Universal Testing machine. At PCS, the Epsilon range of extensometer calibrators provide 80Nm (0.8 micro inches) over a 50mm (2 inch) extension range. These calibrators meet or exceed stringent ISO 9513 and ASTM E83 Class B-1 standards for single axis measurement accuracy and repeatability over the range of most UTMs.

Expedited Calibration of your Universal Testing Machine

We’ve discussed Universal Test Machines and how they are calibrated, but the big takeaway we hope you get from this post is how to minimize the impact of calibration on your production schedule. Most calibration labs have the technical expertise to calibrate your instrument. However, the issue for the engineers, technicians and production managers who use calibrated equipment isn’t the lab’s technical competence, that’s assumed; it’s downtime. There is never a good time to take working equipment out of service, so why not strive to make sure it’s back in service with minimal impact to production due to downtime. PCS is focused on making the average turnaround time for any calibration the quickest in the industry and has the data to prove it. Next time you need your universal testing machine (or any other instrument) calibrated, reach out to PCS for a quote and see just how fast we get the job done.

World’s Heaviest Weight

The million-pound deadweight machine inside a lab at the National Institute of Standards and Technology in Gaithersburg, Md. After a calibration...

5 Reasons Why Your Torque Wrench Needs to be Calibrated

Whether you’re using a torque wrench in a professional setting or in a home garage, you need to know that your fastener is tightened to a specific...